Value Delivered

For this confidential university, Bahnson Environmental Specialties, LLC designed and built a 700-square-foot storage facility that includes -20 degrees Celsius and -75 degrees Celsius storage capabilities.

The facility helps the client securely house the entire tissue collection from 9/11 first responders. This enables future evaluation of health issues that may be a result of exposure to hazardous substances at the World Trade Center site.

Our design included three tiers of redundancy, plus a system to deliver liquid nitrogen, to help maintain frozen conditions in the event of mechanical or utilities failure.

We were able to complete all services for this project on time and on budget.

Client Objectives

The university was constructing a new medical research facility that required storage at -20 and -75 degrees Celsius with limited available building space and relied on our Ultra Low-Temp storage chamber expertise to help achieve their objective.

Solutions

Our comprehensive solution included:

- Design-build of a 700-square-foot storage facility with 300 cubic feet of -20 degrees Celsius storage space and 1,121 cubic feet of -75 degrees Celsius storage space, and 500 cubic feet +4 degrees Celsius storage space.

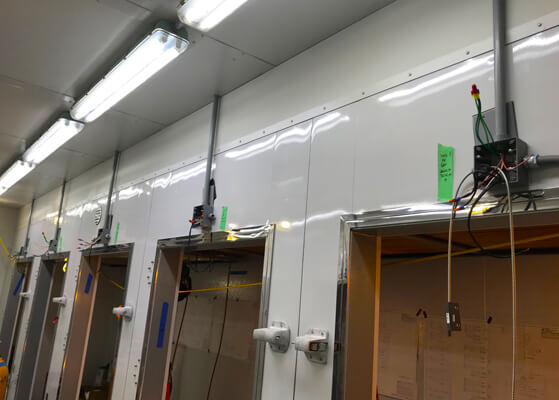

- Eight access doors to the -75 degrees Celsius storage compartments, each with a 5-panel inner doors and internal separation walls to limit temperature rise due to door openings

- Fast recovery of temperature after each door opening.

- Minimal frost build-up. No need to chip ice at the doors.

- Product temperature uniformity of +/-2 degrees Celsius.

- Fabrication, placement, and piping of redundant refrigeration skids

- Site assembly and installation of the freezer system including Project Management

- Assembly and installation of National Electrical Manufacturers Association (NEMA) 12-rated control panels with proportional integral derivative controls

- Startup and validation testing of all systems (considerable reduction in number of validation points and thus cost).

- Owner training on operation of all equipment and controls

- Ongoing routine maintenance

Client Background

This confidential client is a large public university.